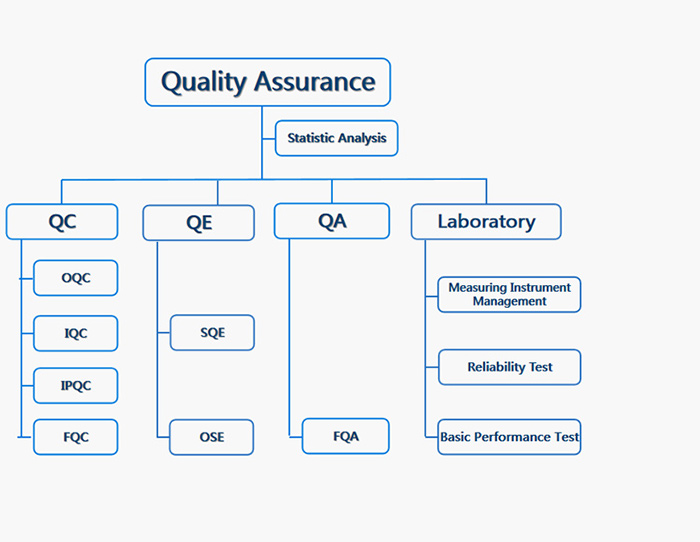

IATF/TS16949 Quality Management System

Founded in 1997, Chongqing Baifu Industry Co., Ltd. (hereinafter referred to as BAIFU), is located in the Shuangfu Industrial Park, Jiangjin District, Chongqing municipality. Specialized in the research, development and manufacturing of automotive air conditioning compressor clutch and riding lawn mower electromagnetic clutch, BAIFU possesses core technologies and independent intellectual property rights as the largest clutch manufacturer in Southwest China.

Production Capacity:BAIFU currently has about 150 employees, including 2 senior engineers, 10 engineers, and 22 senior technicians. The company covers a wide range of processes including stamping, stretching, welding, die-casting, various metal cutting, coating, electrophoresis, electromagnetic coil winding, and assembly lines. The monthly production capacity is over 180,000 pieces of clutches and an annual output value of approximately CNY100 million.

Quality Management:BAIFU passed the IATF/TS16949 quality management system certification in 2005. From product development, trial production, to mass production, every process strictly adheres to the quality management system to ensure product quality.

Applications:The electromagnetic clutches for lawn mowers are widely used in the garden machinery industry (Currently applied by GGP Stiga & Husqvarna mowers). The automotive electromagnetic clutches are extensively used in the automotive industry (models from Chang’an Auto, SUZUKI Chang’an, Great Wall, Geely, Chery, DFSK etc.) and have been adopted by both domestic and international customers.

Endless service

Product excellence

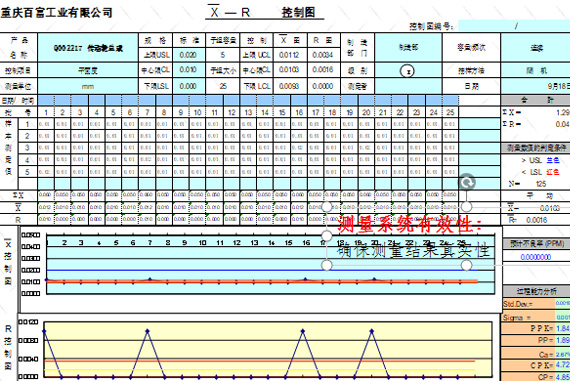

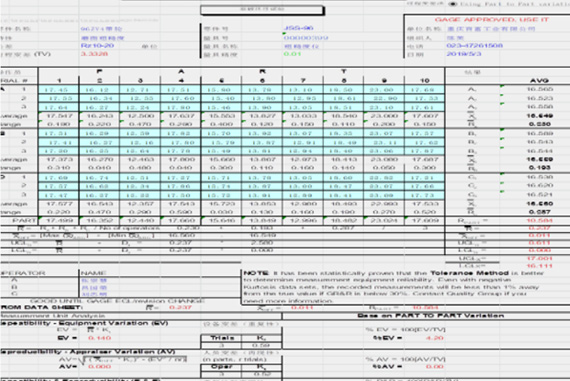

Continuous improvement of the system

- Automated assembly inspection of automotive components

- Motorcycle parts offline full inspection

- Online inspection of machine components

- Full inspection of the clutch assembly line for garden machinery

Quality assurance

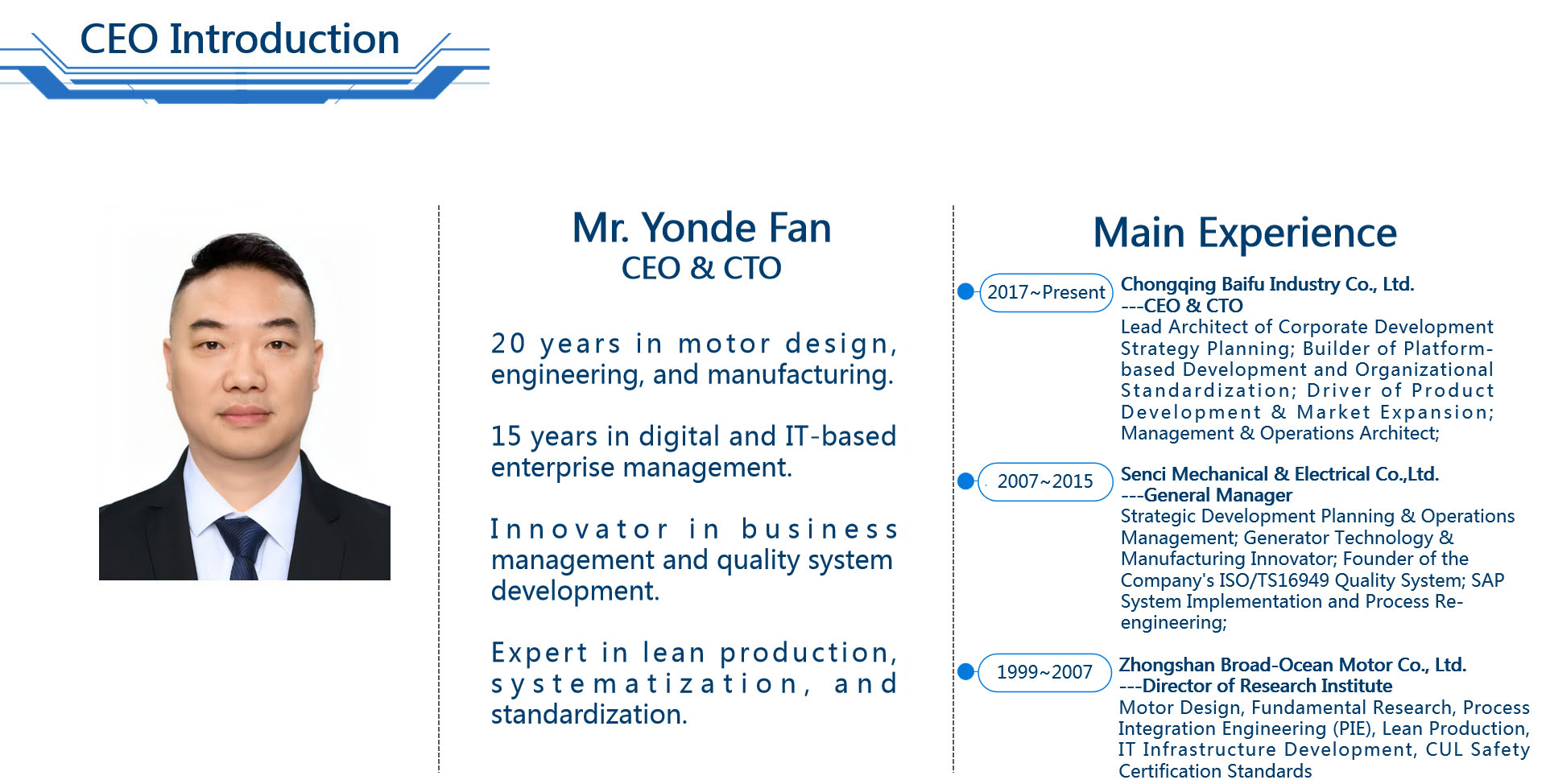

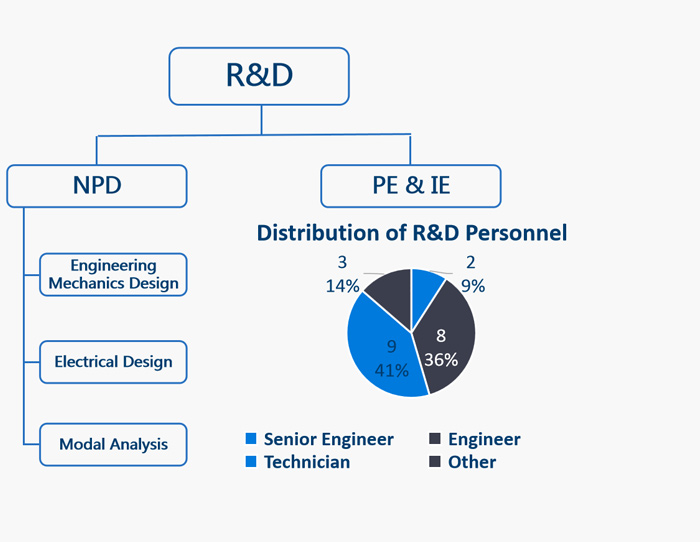

Research development capabilities

High Efficient Core Team

Technology Drives progress

Research and development achievements for the future

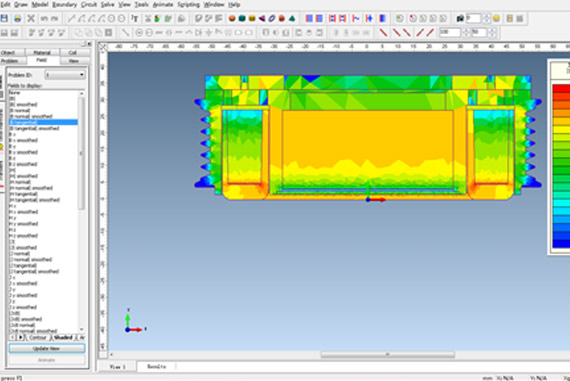

Design tool

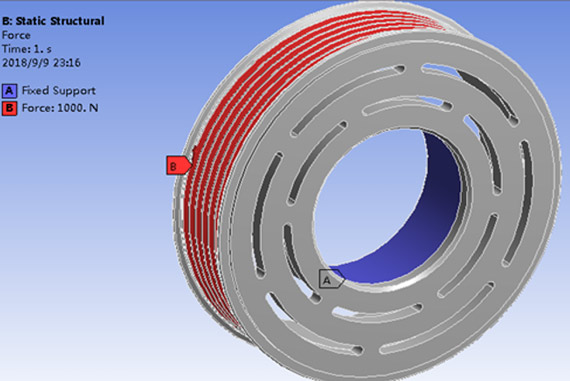

Stress Analysis

Product analysis tools